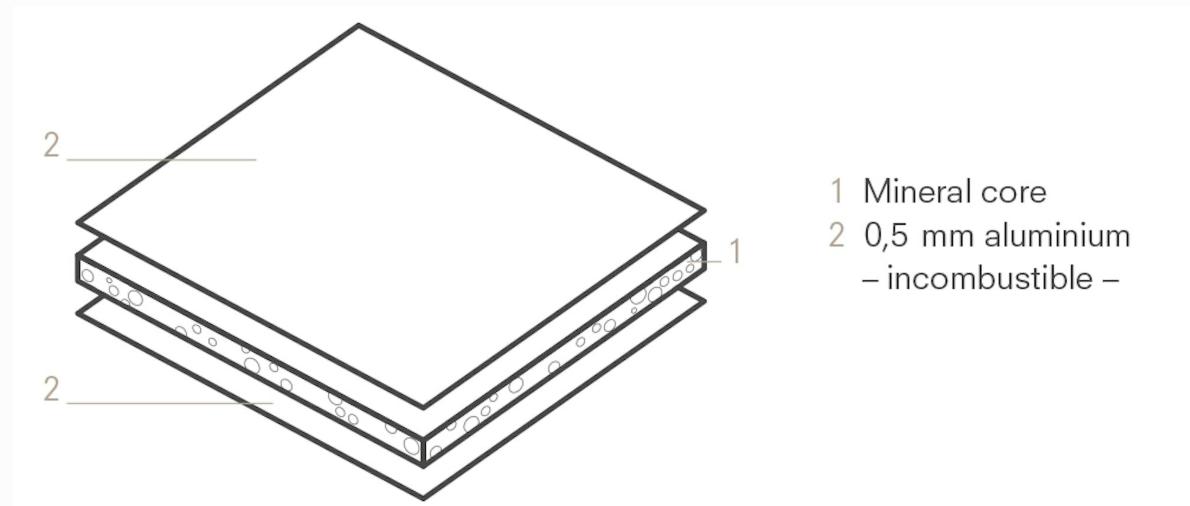

ALUSIGNPANEL® A2 FR is our non-combustible aluminum composite panel ,which composed of 0.50mm 3003H24 aluminum alloy + non-combustible mineral core + 0.50mm 3003H24 aluminum Alloy developed to meet the highest standards of fire classification .

|

Like all the other aluminum composite panel products easy to process, high rigidity, excellent flatness, impact resistance, durability , colourful and ALUSIGNPANEL® A2 FR with non-combustible mineral core passed a A2-S1, d0 fire rating (according to EN 13501:2018 & GB/T8624:2012 ) . |

|

ALUSIGNPANEL® A2 FR ACP fulfils very exacting requirements of the fire safety regulations thanks to the mineral-filled core, and increases the scope for building concepts and design, is the ideal cladding solution for high-rise and high-occupancy buildings.

Specification :

|

Width |

1220mm , 1250mm , 1500mm |

|

Length |

2440mm , 3050mm ,5000mm |

|

Panel Thickness |

4mm , 5mm ,6mm |

|

Alu.Skin Thickness |

0.50mm , 0.40mm , 0.30mm |

|

Alloy |

AA5005H24 / AA3003H24 |

|

Surface Coating |

PVDF coating |

|

Standard |

A2 FR , PVDF coating 1220*2440MM 4MM 0.50MM (AA3003H24 ) |

|

Colors |

Regular color chart options ,accept RAL ,Pantone color code |

|

Others |

Accept customized size and colors . |

Fire-resistance Performance Standard

|

No. |

China |

Germany |

U.S.A. |

France |

EU |

|

GB/T8624 |

DIN 4102 |

ASTM E84 |

NFF16-101 |

EN13501 |

|

|

1 |

A1, A2 |

A1, A2 |

NC |

MO |

A1,A2 |

|

2 |

B1 |

B1 |

A |

M1, M2 |

B1 |

|

3 |

B2 |

B2 |

B, C |

M3 |

C |

Level and Combustion Property

|

Degree |

Item |

Degree |

Item |

|

A |

None-combustion |

B1 |

Hard-combustion |

|

B2 |

Combustion |

B3 |

Combustible |

|

Degree |

Material |

The Combustion Performance Indicators |

|

|

None-combustion |

Class A Material |

According to GB/T8625 test, the average length of the remaining≤35cm (including any residual specimen length≥20cm) for each test and average flue gas temperature peak≤150℃, no specimen back burner the scene; According to GB/T8627 test, their smoke density levels (SDR)≤15; According to GB/T14002 and GB/T14403 test, its calorific value≤4.2MJ/kg, and the specimen thermal emission per unit area≤16.8MJ/m2; Toxicity materials combustion flu gas of the entire non-lethal concentration of≥25 mg/L. |

|

|

Hard-combustion |

Class B1 Material |

According to GB/T8626 test, its combustion properties should be met GB/T8626, and does not allow any dropping of combustion burn the filter paper; According to GB/T8625 test, the average of each specimen remaining length≥15cm (including any residual specimen length≥0cm), and average peak temperature of gas≤200℃in each test. According to GB/T8627 test, their smoke density levels (SDR)≤75. |

|

Aluminum Composite Panels are environmentally friendly and recyclable ,it manufactured with 88% recycled aluminum coil. Using the mass balance approach, we have significantly increased the recycled content without compromising quality or processability and the core materials recyclable too .

Benefits:

1.Reduction of CO2 emissions: The CO2 emissions of the cover sheets have been reduced by 55% compared to conventional processes.

2. Circular economy: Production waste is recycled, the aluminum is remelted, and used for new panels.

3. Environmentally friendly and efficient: The use of secondary aluminum saves fossil resources and reduces greenhouse gas emissions, without requiring adjustments to existing processing equipment .

Products List

- 1