How to Process and install ALUSIGNPANEL Aluminium Composite Panel?

|

Saw Cutting :

|

|

Fretsaw : ladder-Type/plate saw plate saw teeth are inclined at 45°.

|

|

|

Diameter of saw plate :300MM .

|

|

Teeth number : 72 teeth type is usd to cut 5 sheet .Leuco Ref :188389

|

|

96 Teeth type is used to cut gross edge .Leuco Ref :188390

|

|

Diameter of saw plate :250MM .

|

|

Teeth number :60teeth type is used to cut 5 sheets leuco Ref :188939

|

|

80 Teeth type is used to cut gross edge . Leuco Ref :188940

|

|

Thickness of teeth :3.2MM

|

|

Relief angle :15°

|

|

Rake angle :+10°

|

|

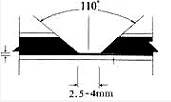

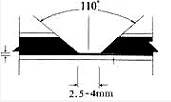

V Type Open-tank process :

|

|

If the back side of aluminium composite panel needs to processed as a V type tank , it is easily formed by using general router .Cutting speed :3000-5000M/Min ,

Feeding speed :25-30M/Min

|

|

|

U type open-tank process :

|

|

Cutting machine with guide plate can be adopted to opening tank .After the V type tank of ALUSIGNPANEL aluminium composite panel finished , it will be very convenient to use .

|

|

|

Riveting :

|

|

Users can use some common equipment to rivet and fasten aluminium composite panel . If ACP is used outdoor , heat seal should be taken into consideration . Self-plugging rivet can connect it only from one dirction .

|

|

|

Bending :

|

|

If the aluminium composite panel is processed on the operation platform, the bending part can be made orderly . Flat punch , press brake and bending mould are suitable for bending .We recommend the bending temperature higher than 10℃

|

|

|

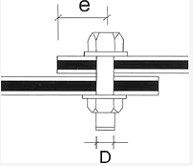

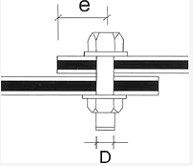

Bolting :

|

|

Considered from deformation limit , formula e≥2D is the best calculation method about the distance between D and e .

|

|

|

Use press brake to process ALUSIGNPANEL aluminium composite panel

|

|

If users adopt press brake to process aluminium composite panel , the calculation formula of Min . Inside radius is: R=15*t (t means the thickness of sheet )

|

|

|

If aluminium composite panel is processed by three roller plate bender :

|

|

Compared with press brake , three rollers plate bender is suitable for bending of larger inner diameter .

|

|

|

Drilling :

|

|

It is easy to drill holes on ACP . We recommend drilling machines specially designed for drilling holes on the aluminium and plastic materials . By the way , the drilling machine should have the function of orientational drilling , if it is used to drill a bigger hole .

Cutting angle : 100°-400°,

helical angle : 30°-50°,

cutting speed :50-300M/Min ,

Feeding speed :0.02-0.5MM/rotate ,

speed drill size : width of screw thread +2MM .

|

|

How to clean and maintain PVDF paint ?

PVDF paint coated on the surface of ALUSIGNPANEL aluminium composite panel needs to be cleaned and maintained professionally . This is not helps maintain the clean surface of building wall ,But also removes the smear which may corrode the paint . Therefore , PVDf paint can be maintain its quality for along tiem .

The claning cycle depends on the enviroment condition and degree of contamination . We suggest that outer wall should be cleaned at least once a year . The inner wall can be cleaned according to the degree of contamination .

Wall cleaning should be conducted manually or by come suitable cleaning equipment , from top to bottom . please do not use any corrosive materials to rub the surface .

1.You should use a large amount of clear water to wasg the surface of panel .

2.Use soft cloth to rub the surface of panel .Soft cloth should be soaked with water-detergent solution .

3.Wash away the dirt on the panel .

4.Check the surface of the panel .To those places still unclear , you can use detergent to clean again .

5.Wash the panel until no detergent is left on the surface .

Note :

Do not wash the panel when the temperature is higher than 40℃ . If the water is volatilized too quickly , it is harmful to PVDF paint .Please pay special attention that you should choose Neutral Detergent to clean the panel .Please do not use strong alkali detergent , Such as potassium hydroxide , sodium hydroxide or sodium carbonate ; Strong acid detergent ,abrasive detergent or paint resolvable detergent .

Before you wash large are surface , you had better do a test on a small piece to make sure it is safe .

More information , please check with website : https://www.alusignpanel.com/services-after.html

Brant Wu

[email protected]